Introduction to Automatic Batching Systems for Manufacturing

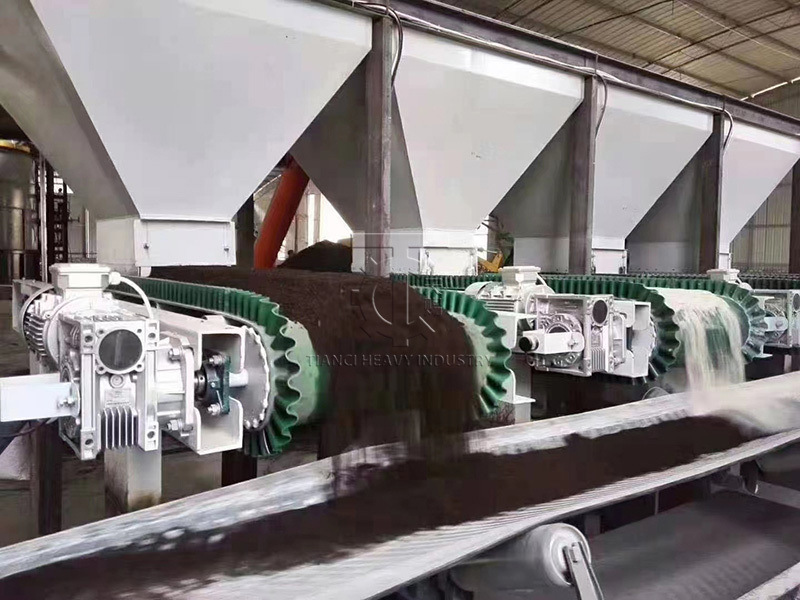

Tianci Heavy Industry's fully automatic batching system is an automatic batching device designed for use with blending, organic, compound, and mixed fertilizer equipment. It automatically adjusts the proportions to meet customer needs. This system is used to weigh, distribute, and mix multiple raw materials individually, replacing manual scales or volumetric metering. It features high metering accuracy, efficient distribution, and a high degree of automation, making it a key component of a complete fertilizer production system. Utilizing microcomputer control, electronic monitoring, and digital indicators, it is easy to control and operate, ensuring precise fertilizer content.

(Process Diagram of Dynamic Batching System)

1. Core Components

The system is divided into a hardware execution layer and a software control layer, which work together to realize a fully automatic batching process.

1.1 Hardware Execution Layer

Responsible for the transportation, metering, mixing and auxiliary guarantee of materials, and matching equipment according to material characteristics.

Conveying equipment: According to the material form (granules, powder, liquid), choose belt conveyor, screw conveyor or pipeline pump.

Measuring equipment: With dynamic weighing modules (such as belt scales, spiral scales) or flow sensors as the core, it collects weight/flow data in real time.

Mixing equipment: such as twin-screw mixers and mixing tanks to ensure that the materials are evenly mixed after proportioning.

Auxiliary equipment: including silos, gates, and dust removal devices to ensure safe material storage and a clean working environment.

1.2 Software Control Layer

It is responsible for issuing instructions, collecting data and closed-loop control, and is the "brain" of the system.

Control system: Use PLC (Programmable Logic Controller) or DCS (Distributed Control System) to accurately execute batching logic.

Human-machine interface (HMI): Parameter setting (ratio, output), operation monitoring and data query can be achieved through touch screen or host computer software.

Closed-loop control algorithm: Real-time comparison of actual measurement value and target value, automatic adjustment of conveying speed, correction of deviation, and ensuring batching accuracy.

(Control System Panel)

2. Core Advantages

Compared with traditional manual batching or static batching, this system has four significant advantages:

High precision: Dynamic metering error can be controlled within ±0.2%~±1% (depending on the material and equipment accuracy), which is much better than manual batching error.

High efficiency: No need to stop for weighing, supporting continuous dynamic operation, the production capacity of a single production line can be increased by more than 30%, while reducing labor costs.

High stability: To avoid subjective issues in manual operation (such as material spillage and misjudgment of proportions), the software automatically records production data to facilitate quality traceability and control.

High flexibility: supports simultaneous batching of more than 10 materials, can quickly switch between multiple recipes, and can adapt to different production needs by modifying parameters through the HMI.

3. Typical application scenarios

The system is widely applicable to process industries that require precise proportioning. Core application areas include:

Fertilizer processing industry: the proportion of organic fertilizer, nitrogen, phosphorus, potassium and other fertilizers used in blended fertilizers.

Building materials industry: proportion of sand, gravel, cement and additives for concrete and dry mortar.

Chemical industry: Mixing and proportioning of various raw materials in the production of fertilizers, coatings, and rubber.

Food industry: grain processing, the ratio of corn, soybean meal, additives and other raw materials in feed production.

4. Ingredient form

The Tianci batching system uses a steel-cone-bottomed material silo with a screw conveyor, vibrator or scraper installed at the bottom of the silo to force the material to be discharged. It is suitable for all forms of materials and especially solves the problem of blockage of granular, powdery and sticky materials. The discharge speed is controllable and the flow rate can be precisely adjusted with metering equipment. The material silo has a simple and sturdy structure and is not easy to deform.

5. Batching system parameters

The entire production process is automatically controlled by a microcomputer;

The LCD can monitor the automatic working status of the equipment;

User operators can formulate, modify and edit production recipes;

The microcomputer can store multiple production formulas;

The electronic hopper scale adopts a dual-speed feeding control method to ensure fast and accurate feeding;

Automatic parking positioning accuracy: ±10mm;

The inner track gauge, car body height and discharge port form are shown in the drawings (can be modified according to user's process);

Maximum weighing capacity of single hopper: 300~1500kg;

The feeding port of the electronic hopper scale of the weighing vehicle is equipped with a sealing device that can automatically rise and fall, as well as a dust removal system, which can effectively solve the problem of dust flying during the feeding and unloading process, making the production site environment clean and orderly;

Ambient temperature: -20℃~+50℃ at the weighing car working site, 0℃~+30℃ in the computer control room;

Power supply:380V±10%/50Hz,480V±5%/60Hz,400V±10%/50Hz,220V/60Hz, 11~37Kw,

Working mode: automatic operation by microcomputer, semi-automatic operation by control room.

Finished Fertilizer Batching Finished Product Display:

Project Cases:

After-Sales Service:

6. Q&A on the fully automatic batching system

Q1. What types of materials can the fully automatic batching system be adapted to?

A: It can cover most forms of industrial materials, including granules (such as nitrogen, phosphorus and potassium granules, organic fertilizer granules, sand and gravel, soybean meal), powders (such as cement and flour), liquids, etc. Different materials will be matched with exclusive conveying and metering devices.

Q2. What is the system’s batching accuracy?

A: Dynamic metering error can typically be controlled within a range of ±0.2% to ±1%, depending on material characteristics and equipment accuracy. For industries requiring high precision, such as chemicals and fine ceramics, precision can be further improved through customized high-precision components.

Q3. How many types of materials can the system process simultaneously?

A: Conventional systems support the batching of 2 or more materials , with 3-6 material bins commonly configured. Customized systems can achieve the simultaneous batching of more than 10 materials, meeting complex formula production needs.

Q4. Can the system quickly switch production recipes?

A: Yes. Recipe parameters can be modified directly through the human-machine interface (HMI). The system automatically adjusts material ratios and conveying speeds without requiring major hardware adjustments. This makes it particularly suitable for high-variety, small-batch production.

Q5. Does the system require dedicated operators?

A: Operation and monitoring can usually be completed by one or two trained personnel without requiring extensive manual labor. Tianci Heavy Industry provides professional training covering parameter settings, daily inspections, and basic fault diagnosis.

پیام شما باید بین 20 تا 3000 کاراکتر باشد!

پیام شما باید بین 20 تا 3000 کاراکتر باشد! لطفا ایمیل خود را چک کنید!

لطفا ایمیل خود را چک کنید!  پیام شما باید بین 20 تا 3000 کاراکتر باشد!

پیام شما باید بین 20 تا 3000 کاراکتر باشد! لطفا ایمیل خود را چک کنید!

لطفا ایمیل خود را چک کنید!