1. Introduction to High-pressure Roller Ball Press

The high-pressure double-roll ball press, manufactured by Zhengzhou Tianci, is a specialized piece of equipment engineered to compress powdered raw materials into dense, solid pellets.Its industrial applicability is exceptionally broad. It is capable of processing a diverse range of raw materials—including aluminum turnings, activated carbon, alumina, bauxite, caustic soda, charcoal, clay, coke breeze, coal, cryolite, chemical fertilizers, plastic powder, limestone, pigments, urea, and potassium fertilizers—for agglomeration, granulation, and briquetting purposes.

High Pressure Roller Ball Press Machine for Coke Chips Pelletizing - Customer Site

The core value of this equipment lies in its practicality: it minimizes dust emissions, optimizes the bulk density of raw materials for precise output regulation, enables raw material recycling and reuse, and streamlines raw material transportation.

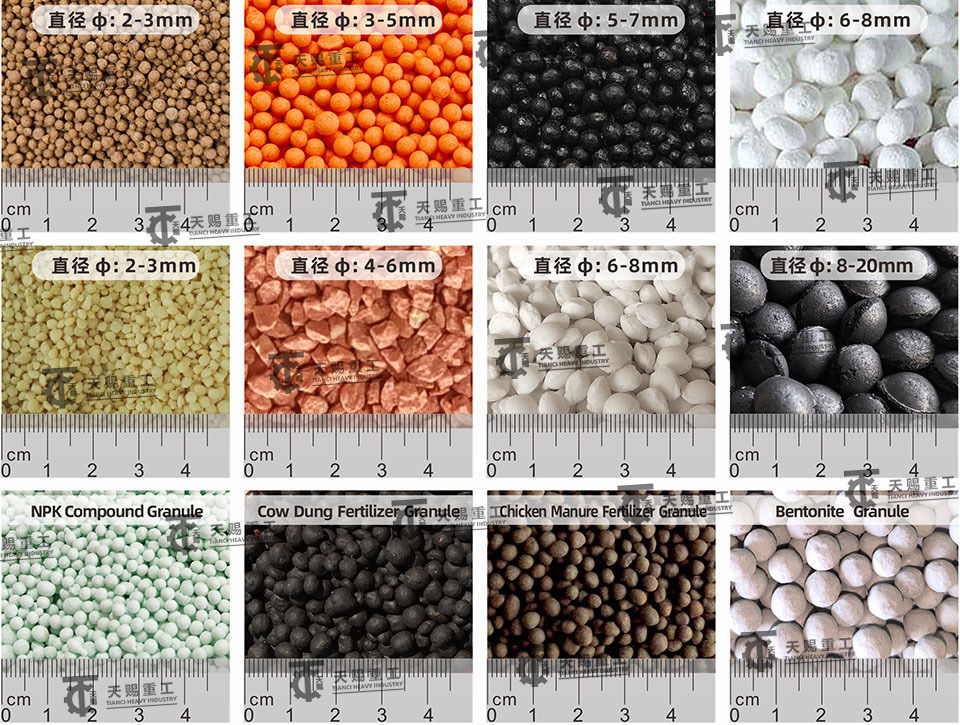

Tailored to specific process requirements, it is primarily used to compress dry powder raw materials into pellets with a diameter of 3 millimeters or larger. The pellets produced exhibit consistent forming quality, meeting the subsequent production and application demands of various industries.

2. raw materials and materials used in briquetting

2.1 Applied raw materials

Aluminum chips, activated carbon, alumina, bauxite, caustic soda, charcoal, clay , coke chips, coal, cryolite, fertilizers, plastics, limestone, pigments, urea, potash salt...

2.2 Material requirements

2.2.1 The particle size of the material can be between 30 and 200 mesh.

2.2.2 Hard metal objects are not allowed in the material, otherwise the roller surface will be damaged.

2.2.3 The material supply must be sufficient. It is advisable to use an adjustable speed screw feeder and adjust the supply of new material by observing the return material volume.

3. Brief description of working principle

The pre-pressed material discharged from the pre-pressing screw is forced into the central area of the rollers via the ball-pressing nozzle. The rollers, operating at equal rotational speed but in opposite directions, apply compressive force to the material. During this process, the unit pressure acting on the material increases progressively, peaking at the line connecting the centers of the two rollers. As the material passes this center line, the unit pressure decreases gradually, inducing the material to enter a pellet-dropping phase until the pellets are fully discharged.

With proper adjustment of the main machine speed and pre-pressing speed, the equipment can achieve one-step pellet formation. When the screened return material is mixed with fresh material for re-pressing, the return material must be free of excessively large lumps; it is recommended to crush the return material into particles of 2-3mm in size. In cases where oversized lumps are present in the return material, or the proportion of return material in the return-fresh material mixture exceeds 50%, the rotational speed of the pre-pressing screw shall be reduced. Failure to do so will likely result in motor overload.

4. Parameters

DH Series Dry Roller Granulator

|

model

|

DH240

|

DH360

|

DH450

|

DH650

|

DH800

|

DH1000

|

|

Roller diameter (mm)

|

Φ240

|

Φ360

|

Φ450

|

Φ650

|

Φ800

|

Φ1000

|

|

Effective width (mm)

|

80

|

170-230

|

250-450

|

290-330

|

380-450

|

500

|

|

Roller speed (rpm)

|

15, 20, 26, 32

|

14, 18, 24, 30

|

10-25

|

10-25

|

10-25

|

10-20

|

|

Maximum molding pressure (KN)

|

320

|

800

|

1300

|

2100

|

2900

|

3500

|

|

Maximum thickness of rolled sheet (mm)

|

4

|

8

|

12

|

16

|

25

|

35

|

|

Slab output *(kg/h)

|

300

|

1600

|

3000

|

6000

|

10,000-16,000

|

26000

|

|

Finished product size (mm)

|

0.5-30

|

0.5-30

|

0.5-30

|

0.5-30

|

0.5-30

|

0.5-30

|

|

Finished product output *(kg/h)

|

180

|

900-1300

|

1800-2500

|

3500-4000

|

6000-8000

|

13000-16000

|

|

Host power (kw)

|

7.5

|

30-37

|

55-75

|

90-110

|

21-250

|

315

|

|

Total installed capacity (kw)

|

20

|

55

|

90

|

175

|

298

|

450

|

|

Overall dimensions (LWH) (mm)

|

1500×1300×2500

|

2350×2200×2900

|

2600×2200×2900

|

3600×2800×3200

|

4200×3500×3500

|

3800×3500×3800

|

|

Total weight of equipment (t)

|

7

|

10

|

15

|

25

|

33

|

45

|

Note: The tablet rolling output and finished product output are reference values; the screen plate shall be determined based on the properties of the material.

پیام شما باید بین 20 تا 3000 کاراکتر باشد!

پیام شما باید بین 20 تا 3000 کاراکتر باشد! لطفا ایمیل خود را چک کنید!

لطفا ایمیل خود را چک کنید!  پیام شما باید بین 20 تا 3000 کاراکتر باشد!

پیام شما باید بین 20 تا 3000 کاراکتر باشد! لطفا ایمیل خود را چک کنید!

لطفا ایمیل خود را چک کنید!